Precise measurement of water parameters, which has to undergo the treatment process, is a prerequisite for the correctness of subsequent stages of assigning it a specific functionality, always dependent on the recipient’s needs, and these may be different – especially if we have in mind larger commercial investors, such as industrial plants (including those conducting operations requiring extremely high safety standards, including water installations).

Well-made measurement also ensures effective and safe dosing of chemicals – disinfecting and regulating the physicochemical state of water. Depending on the industry in which the customer operates, we perform, among others, process, boiler and cooling water treatment.

Correct measurement is essential to successfully carry out dosing of the right chemicals, which in turn determine the effective disinfection or regulation of pH level of the water. Remember that disinfection is not only the process of filtering out pathogenic microorganisms, but also the addition of agents that ultimately purify the water.

Chlorine is the most popular disinfectant – because this process uses different compounds of this element (most often sodium hypochlorite, but also chlorine dioxide or chlorine gas) it is also necessary to develop appropriate technologies that would prove to be the most effective and at the same time provide maximum safety in the process of disinfection and overall water treatment.

Depending on the water to be treated, other substances are also dosed.

For example, in the case of cooling water treatment these include: biocides, which inhibit the growth of bacteria and other pathogenic microorganisms, if the customer is interested in boiler water treatment, we will offer dosing of preparations binding oxygen, but also those correcting pH and e.g. corrosion inhibitors.

To dose chemicals effectively and safely, it is essential to use good quality measuring and dosing equipment – such as dosing pumps.

Granimex offers various types of dosing pump systems, which can always be optimally adapted to the needs of specific investors. Our pumps operate efficiently regardless of the conditions “determined” by water and its flow dynamics.

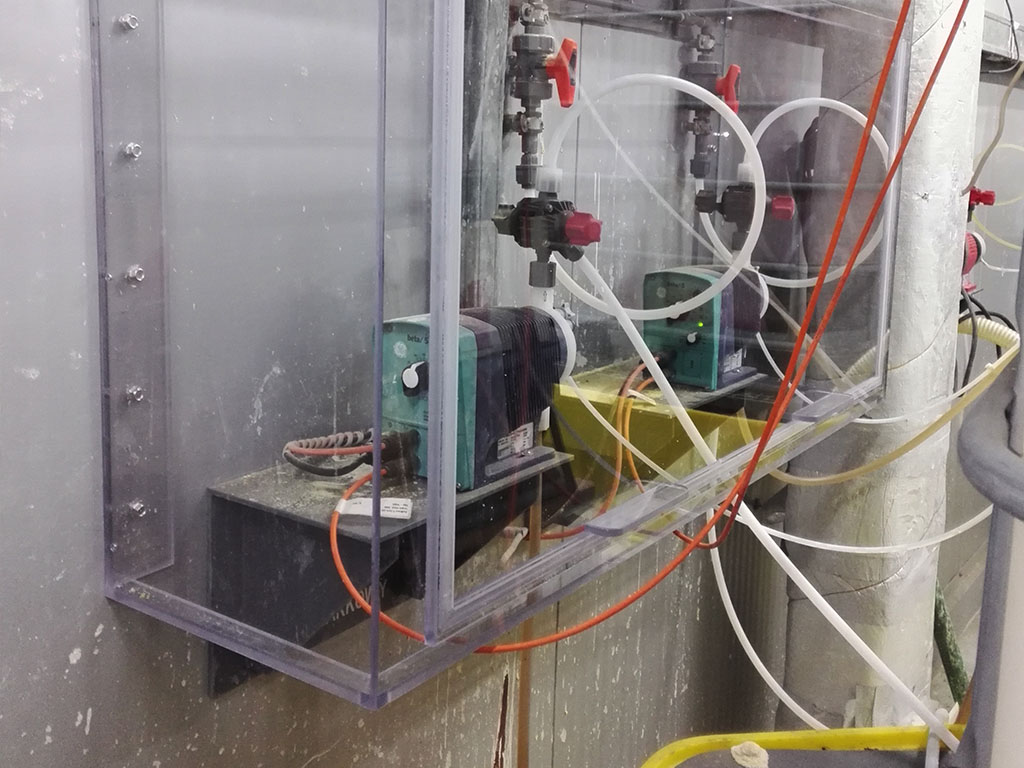

Dosing pumps are part of a larger system of devices ensuring the proper dosage of various types of disinfectants and water regulating agents – i.e. dosing stations.

Such a system consists, for example, of a (diaphragm) pump, solution tank, supply lines and valves.

The system is by definition multifunctional, which means that it controls not only the dosing of specific chemicals, but also other water parameters such as flow and conductivity. Their values largely determine the final efficiency of the entire water treatment process.

A chemical dosing system, just like other systems of this type, needs certain procedures to function properly – Granimex provides professional service of dosing stations, i.e. control of all water parameters (to verify correctness of applied preparations and their doses).

The dosing technology we offer (based on a pump system) is comfortable for the user. Why? Not only it ensures optimum safety, but it is also largely automatic, which means that certain mechanisms are functionally adjusted to the current state of water, e.g. the value of its flow.

Modern pump materials are another advantage of the dosing system offered by Granimex – easy to maintain, resistant to corrosive agents and thus highly efficient in the water treatment process.

We pay special attention to the safety of the entire process of dosing and adjusting the chemical composition of water, thus our offer includes not only ready-made solutions but also professional advice on designing and implementing systems.

We have at our disposal the highest quality control and measurement equipment, compliant with all required European and national standards. Thanks to this we are sure that the measurements made using it are error-free.

All the equipment we use undergoes detailed and rigorous performance tests (in various conditions), and therefore our offer is addressed to various, even the most demanding customers (e.g. from the chemical industry and other, particularly “sensitive” in terms of environmental safety).

We use materials from the best suppliers and measuring technologies that allow us to perform water level tests with the highest safety standards, which in this case means non-invasiveness and maximum reduction of any technical risk.

Never save on the quality of control and measurement equipment – failures can cause (especially in large industrial plants) a serious threat to the environment and people.

Control and measuring devices must be of the highest quality, which is confirmed by appropriate standards and certificates, such as SIL (Safety Integrity Level). We mean here, among others: pressure and temperature transmitters, flow meters or components of automation systems.